Add to Cart

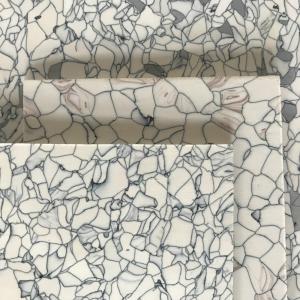

Low Voltage SMT Consumables PVC Roll Floor Cover Insulation Sheet Type

PVC floors are provided with permanent antistatic property, stable and not affected by temperature and humidity of the interior of cleaning room. The surface of floors are smooth to protect the chemical pollution and easy to clean and maintain for floors. The PVC rolls are provided to completely solve the enlargement of the chink of PVC tiles.

PVC tiles and rolls are widely used in the area of electronic, computer, telecommunication,medicament and sanitation ,transportation carriages etc.

Specifications:

|

System resistance |

Conductive1.0×106Ω |

|

Dissipation:1.0×06Ω 1.0×109Ω |

|

|

Static full decay period |

2S |

|

Starting voltage |

V | 100V |

|

Amount of wear |

≤0.02g / c |

|

Combustion property |

FV - 0 |

|

Residual hollow strength |

≤0.15MM |

|

Rate of size change at heating |

≤0.20% |

|

Product components |

Anti-static PVC floor (tile and roll) |

|

PVC Welding strips |

|

|

Copper strips 20MM×0.03MM |

|

|

Conductive glue |

|

Name |

Floor Length (MM) |

Floor Width (MM) |

Floor Thickness |

|

PVC tiles |

300 * 300 / 600 * 600 / 900 * 900 /1200 * 1200 |

2.0MM/2.5 MM/ 3.0 MM |

|

|

PVC roll |

1700 ~ 1900 |

1500 ~ 2000 |

2.0 MM/2.5 MM |

Installation

Step 1_Select the laying direction direction and fix the guide line on base.

Step 2_Laying the copper strips by 20MM×0.03MM secton, 1.2M×2.0M spacing.

Step 3_Apply the glue.

Step 4_Laying the floors and pressing with a 60~80KG flooring roller.

Step 5_Groving and hot relding with plastic strips.